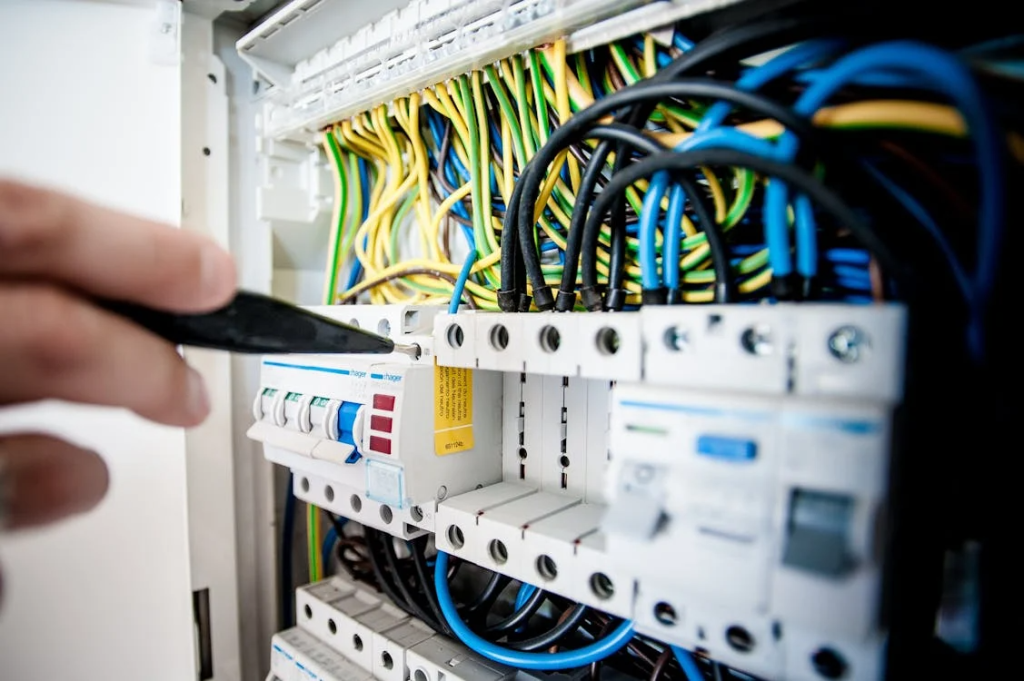

Residual Current Devices (RCDs) are a critical safety feature in electrical systems, designed to prevent electric shocks and other electrical hazards. RCD testing is essential to ensure these devices are functioning correctly.

When it comes to how often should you conduct RCD testing, it is crucial to adhere to the appropriate guidelines to ensure safety and compliance with regulations.

While RCD testing might seem like a minor task, regular checks can prevent dangerous accidents and improve the longevity of your electrical systems.

In this article, we will explore the importance of RCD testing, the Australian regulations for frequency, and how thermal imaging Melbourne can further enhance the safety of your electrical systems by identifying potential risks beyond just the RCD.

Why RCD Testing is Essential

RCDs are designed to detect an imbalance between the live and neutral wires in an electrical circuit, cutting off power when leakage or faults are detected. This is particularly important in preventing serious accidents such as electric shocks or electrical fires.

However, like all safety devices, RCDs can degrade over time, which is why RCD testing is necessary to verify that they are working correctly.

The Role of RCDs in Electrical Safety

RCDs are part of your electrical system’s first line of defence against electrical faults. Their primary function is to detect leakage currents and disconnect the circuit in the event of a fault, which could prevent electric shocks from occurring.

A working RCD can be the difference between a harmless event and a life-threatening situation. As a result, keeping these devices in proper working order through regular testing is vital.

Risks of Not Conducting RCD Testing

If RCDs are not tested regularly, they may not function when needed. Faulty RCDs could allow electrical faults to go undetected, resulting in electric shocks, fires, or equipment damage.

This is why understanding how often you should conduct RCD testing is key to maintaining a safe environment, whether at home, in the workplace, or on industrial sites.

Australian Standards for RCD Testing

In Australia, RCD testing is regulated by standards set by Standards Australia and other regulatory bodies. These guidelines specify the minimum frequency for testing and the procedures that must be followed to ensure the RCDs are functioning correctly.

The key standard for RCD testing is AS/NZS 3760, which outlines how electrical appliances and safety devices like RCDs should be tested.

AS/NZS 3760 Requirements for RCD Testing

The AS/NZS 3760 standard provides clear guidelines on how often RCDs should be tested. It mandates that RCDs be tested at least every six months for most environments.

This regular testing is crucial to ensure they are working as expected and to prevent any risk of failure. The standard requires that:

- RCDs are tested at regular intervals (typically every six months) to ensure proper functionality.

- A qualified professional should perform the testing using the appropriate equipment.

- Visual inspections of the RCD should also be performed regularly to ensure there is no visible damage.

Frequency of RCD Testing in Various Environments

The required frequency of RCD testing may vary depending on the environment in which the RCDs are used. For instance:

- Residential settings: In homes, RCD testing should be performed at least every six months.

- Commercial settings: In workplaces, especially those with high electrical usage, RCDs should be tested more frequently, such as every six months or annually, depending on the risk level.

- High-risk environments: In industrial or construction sites, where equipment is subject to higher levels of wear and tear, testing may be required more frequently.

Adhering to these standards ensures compliance and prevents electrical hazards.

How RCD Testing Is Done

RCD testing involves using a testing device to check the functionality of the device, ensuring that it trips when there is a fault. There are different methods of testing, including push-button tests and more comprehensive testing using a dedicated RCD tester.

Push-Button Test

The simplest method for testing an RCD is the push-button test. Most RCDs have a built-in test button that simulates a fault condition. By pressing this button, you can verify that the device trips and cuts off power.

However, this is a basic test and only checks whether the RCD will trip under a simulated fault. It does not measure the trip time or verify the RCD’s sensitivity to leakage currents.

Using an RCD Tester

For a more thorough test, an RCD tester is used. This device can simulate a fault by introducing a small leakage current into the circuit and measuring how quickly the RCD responds.

The tester will ensure that the RCD trips within the required time frame, typically 300 milliseconds. This type of test is more accurate and provides a clearer picture of the RCD’s condition.

Role of Thermal Imaging in RCD Testing

While RCD testing is essential for ensuring the safety of your electrical system, using thermal imaging Melbourne services can further enhance your electrical safety protocols.

Thermal imaging can identify overheating electrical components that may not be apparent through standard testing.

This type of inspection uses infrared cameras to detect hot spots in electrical circuits, which could indicate faulty wiring, overloaded circuits, or other issues that could lead to failures or electrical fires.

How Thermal Imaging Complements RCD Testing

Thermal imaging can identify electrical components that are at risk of failure due to overheating.

If an RCD is functioning but is not protecting against overheating components, it might not provide the full safety coverage needed. By integrating thermal imaging with RCD testing, you can gain a more complete understanding of the electrical system’s health.

This is especially useful in larger industrial environments or in high-risk areas, where the potential for overloads or component failure is higher.

Benefits of Thermal Imaging

Thermal imaging can help detect overheated electrical panels, connections, and circuits, areas of excessive heat in electrical equipment that might indicate imminent failure and poor connections or faulty wires that may not be detected through standard inspections.

When combined with regular RCD testing, thermal imaging offers an additional layer of protection, ensuring that your electrical system is not only safe in terms of leakage protection but also free from underlying faults that could lead to more severe issues.

How Often Should RCD Testing Be Done?

As mentioned earlier, RCD testing should generally be carried out every six months in residential and commercial settings.

However, the frequency may vary depending on the environment and the nature of the electrical system. Below are specific recommendations for different scenarios:

Residential Settings

For typical household use, RCD testing should be conducted at least once every six months. However, if your household experiences significant electrical usage or you have elderly family members, testing more frequently may be necessary.

Commercial and Industrial Settings

In commercial and industrial environments, RCDs should be tested at least once every six months, especially in environments where the electrical system undergoes heavy use.

High-risk environments such as construction sites or factories may require more frequent testing, as the electrical systems are exposed to more stress.

After Repairs or Modifications

Any time electrical repairs or modifications are made to the system, RCD testing should be done to ensure that the changes do not affect the functionality of the RCDs.

Additionally, after power surges or electrical storms, testing should be conducted to ensure that the system has not been compromised.

Frequently Asked Questions

How often should RCD testing be done in residential homes?

In residential homes, RCD testing should be done at least every six months. However, if the electrical system is old or heavily used, more frequent testing may be necessary.

Can I test my RCD myself?

While you can perform the basic push-button test on your RCD, it is recommended that a licensed electrician conduct a thorough RCD test using professional equipment to ensure proper functionality.

What should I do if my RCD fails the test?

If your RCD fails the test, it should be repaired or replaced by a qualified electrician to ensure that your electrical system remains safe and compliant with regulations.

Conclusion

RCD testing is essential for ensuring electrical safety in your home or workplace. Conducting regular tests every six months, as outlined in the Australian AS/NZS 3760 standard, will help protect people from electric shocks and electrical fires.

By incorporating services like thermal imaging Melbourne, you can further enhance the safety of your electrical systems, ensuring that not only are your RCDs functioning properly, but your entire system remains free of underlying faults.

Regular maintenance and testing of electrical systems are key to preventing accidents and ensuring long-term safety.